Aluminum electrolytic capacitors use instructions

Aluminum electrolytic capacitors may cause an explosion, fire, or other serious trouble if not used under specified operating

conditions. Please familiarize yourself with the instructions given below before using these capacitors

Operating temperature and ripple current

1. Keep the operating temperature and ripple current in specified ranges. Applying an excessive current to a capacitor will overheat it, resulting perhaps in short-circuit, ignition, or other fatal fault.

2. A capacitor is also a heating component itself. Please be on guard, remembering that it heats up the inside of the equipment. Run the unit under normal conditions and check the temperature of the surroundings of the capacitor.

3. The permissible ripple current tends to decline with a rise in the atmosphere temperature (the temperature of the surroundings of the capacitor). Consider a permissible ripple current at the maximum predictable atmospheric temperature. Allow also for the changes in frequency.

Applied voltage and connections

1. Capacitors have polarity. Applying a reverse voltage or AC voltage to a capacitor may cause a fire or other fatal fault.

2. Use a bipolar capacitor for circuits whose polarity reverses. However, in this case, like any other case,refrain from using such a capacitor in AC circuit.

3. When an AC component is superimposed on a DC voltage, prevent the peak value from exceeding the rated voltage. An excessive voltage may cause a short-circuit, fire, or other fatal fault.

4. When connecting more than one capacitor in parallel, consider the resistance of the wiring. Establish the connections so that the wiring resistance will be equal at every capacitor.

5. When more than one capacitor is connected in series, all capacitors must be of identical ratings. Then connect the balancing resistors in parallel. At that time, design the circuit so that the voltage levels applied to all capacitors become equal.Check that the voltages applied to capacitors do not exceed a rated voltage.

6. Do not use such a capacitor for a circuit that is repeatedly charged and discharged quickly. If you are to use such a capacitor for a welding unit or for other charging and discharging purposes, use a capacitor designed on a separate basis.

7. Even slow recharging may shorten the service life of a capacitor if its voltage changes greatly. Check it sufficiently as installed on a larger machine or consult Capsun.

Capacitor insulation

1. Do not connect the blank terminal (reinforcing terminal) of a multi-terminal (three- or four-terminal) product of the snap-in type to another circuit. It may cause a short circuit.

2. The external sleeve of the snap-in type has no insulator. If you need a sleeve with an insulator, consult Capsun.

3. Ensure a completely open circuit between the case and the cathode terminal, and between the anode terminal and circuit pattern

Operating conditions

1. A splash of water, salty water, oil or other electrically conductive liquid on a capacitor or using a capacitor when it has dew on it may cause a breakdown. Oil on the rubber sealing or safety vent may cause a decline in airtightness. Do not use a capacitor with liquid on it.

2. Do not use or leave a capacitor in a place where there is a hydrogen sulfide, nitrous acid, sulfurous acid, chlorine, bromine, or other halide compound gas, ammonia, or other hazardous gas. The ingress of any of the aforementioned gases into a capacitor may corrode it. Avoid fumigating and spraying an insecticide as well.

3. Do not use or leave a capacitor in a place exposed to ozone, ultraviolet ray, or radiation.

4. Do not use a capacitor in a place where vibration or impact is excessive.

Installa tion Before installaton

1. Do not reverse the polarity. Do not use a capacitor to which a reverse voltage is applied, even if it looks problem-free. It must be greatly damaged.

2. Do not tighten the curled part (case sealed part) with a mounting fitting or otherwise stress it. Any such practice may cause a liquid leak or sleeve breakage.

3. Dropping or otherwise impacting a capacitor may result in a decline in its electric performance,causing a breakdown. Therefore do not cause an impact on it.

4. Do not reuse a capacitor which has been installed on a machine and energized. No capacitor can be reused except for those removed to measure their electric performance for a periodic checkup.

Method of installation

1. Do not make the safety vent (cap side) of a screw terminal type face downwards. The safety vent may let the electrolyte or compound leak.

2. Do not install a wiring or circuit pattern near the safety vent. When the safety vent is activated, the electrolyte may jet out, resulting in a fire or other secondary accident.

3. Avoid installing a heating part around a capacitor or in back of a printed wiring board (beneath the capacitor).

4. Do not hamper the activation of the safety vent. Above the safety vent (where a screw terminal type is installed on the terminal side, or snap-in type on the case bottom), allow for the following clearances:

Capacitor diameter Clearance

20∼35 mm dia or more 3 mm or more

40 mm dia or more 5 mm or more

PS2, US2 series 1 mm or more

On-board self-supporting

type (snap-in type) capacitor

1. Soldering such a capacitor as floated from a wiring board may result in one of its terminals breaking or its pattern peeling off when vibrated. Insert a capacitor correctly and tightly into specified holes in the wiring board, then solder it.

2. Flux on the rubber sealing may result in corrosion. Therefore do not let any flux stick to any part other than the terminals.

3. Perform soldering at 260°C for no more than 10 seconds or at 350°C for no more than 3 seconds.Exceeding any specified soldering condition may result in a decline in its electric performance,leading to trouble. Dot not let the tip of the soldering iron contact the capacitor.

4. For cleaning flux, Capsun recommends an aqueous or upmarket alcohol detergent or isopropyl alcohol. The recommended concentration of flux with regard to a detergent is 2wt% or less.Excessively high flux concentration may cause corrosion due to the halide. For other detergents,consult Capsun.

5. Do not let any flux stick to any part other than the terminals.

6. Dry the detergent well and do not let any of it remain on the capacitor. Even when you are not cleaning the flux, dry the flux itself. A residue of detergent or flux may cause the halide to penetrate the rubber sealing, leading to corrosion. The snap-in type comes in models protected with epoxy resin. For such models, consult Capsun.

7. When fixing a board and a capacitor with a coating agent or fixative, use a substance containing no halide compound.

In that case, dry the flux or detergent well in advance, then apply a coating. Do not let the coating block the entire surface of the sealing. Any halide compound contained in the coating may result in corrosion.

8. If the safety vent of the capacitor is installed on the printed wiring board, drill a gas bleeder hole to let out the gas when the valve is activated, according to the location of the safety vent. 9. Do not twist or otherwise physically move the capacitor after soldering it on a printed wiring board.

10. Do not solder a capacitor as dipped in a solder bath. Solder it only to the back face of the opposite side to the capacitor, via a printed wiring board.

11. Do not use a fixative or coating agent containing a corrosive, such as a halogen-based solvent.

12. Avoid whenever possible the use of an ozone-depleting substance used in a detergent or other material, in order to protect the earth.

Screw terminal capacitor

1. The terminal screws, recommended tightening torques, and permissible terminal currents are as listed below. Consult Capsun if you wish to use such a capacitor on a machine that vibrates greatly.

Terminal Recommended torque (permissible level) Permissible terminal current

M5 2.2(1.5∼3.0) 60

M6 3.0(3.0∼3.5) 100

M8 7.5(7.0∼8.0) 120

2. The terminal screws furnished in a separate shipment are geared to wires no more than 2 mm thick.For wires more than 2 mm thick, ensure a screw length allowing for that thickness.

3. Capsun recommends a bar hole diameter of 6 mm for M5. An excessively large hole diameter may result in poor contact between the terminal surface and bar, causing a local heatup and thus a breakdown.

Storage

1. Store all capacitors indoors at a temperature of 5-35°C, at a humidity of no more than 75%RH (25°C), avoiding direct sunlight. The maximum shelf life of capacitors is 3 years. All capacitors which have been on the shelf for more than 3 years have an excessively high leakage current. Treat them with appropriate voltage and use them.

2. Store them under the same operating conditions as mentioned above, except for the temperature and humidity.

3. Store them as packed whenever possible.

4. Restriking may have caused an electric charge. Do not touch the terminal with a bare hand. Any such touch might give you an electric shock. Discharge all capacitors with a resistor (10-100?) or a discharge plate before use

Test run

1. Do not touch terminals of a capacitor with a bare hand. Any such touch might give you an electric shock.

2. Do not short-circuit a capacitor between terminals with an electrically conductive material.

3. Do not apply an acid, alkali, or other electrically conductive solution to a capacitor.

4. For the operating conditions of capacitors, check the "Design Operating Conditions.

Maintenance and servicing

1. Conduct a periodic checkup on capacitors for industrial equipment. The checkpoints are:

(1) Appearance: Status, liquid leakage and other considerable trouble with the safety vent

(2) Electric performance: Capacity, loss, leakage current, and other items specified in the delivery specifications.

The standard temperature for measuring electric performance is 20°C. Leave a capacitor at 20°C and wait for the inside of the capacitor to reach a specified temperature before taking measurements. To learn whether to use such a capacitor, consult Capsun. Before a periodic checkup, turn off the switch and discharge the capacitor completely.

2. Replace all capacitors whose service lives have reached their end. When making a replacement, replace all

capacitors. Using an old one together with a new one may cause an imbalance in the ripple current or voltage sharing

In an emergency

1. If a gas is detected while such capacitors as installed are used, turn off the main power of the installation or unplug the power cord from the wall outlet.

2. When the safety vent of a capacitor is activated, a hot gas exceeding 100°C will jet out. Do not make your head come close to it or go close to a place exposed to the gas.

3. Should a gas jet enter your eye, wash it immediately with clean water.

4. Should an electrolyte get into contact with your skin, wash it with soap and water. Never put it into your mouth

For scrapping

1. Scrapped capacitors are classified as scrapped metal. In the case of burial, they are handled as controllable industrial wastes because of the nature of the contents (electrolyte). Commission the task to a specialist industrial waste disposal agent. Make sure that no waste product enters the market.

2. Most of the material is aluminum and cannot be completely burned. In burning, consider the following:

?Burning them as enclosed may cause an explosion. Either open up a hole or bust the opening.

?Because of the exterior material (polyvinyl chloride), cold burning may cause emissions of hazardous gases. Burn the material at high temperatures. (Burning requires the sorting of exterior material.)

3. Demolishing a capacitor may cause an injury, electric shock, or other trouble. Therefore avoid it.

Other

1. For details, see the Guidelines on the Operation of Fixed Aluminum Non-solid Electrolytic Capacitors for Electronic Equipment EIAJ RCR-2367.

2. For questions, consult Capsun or http://www.szcapsun.com

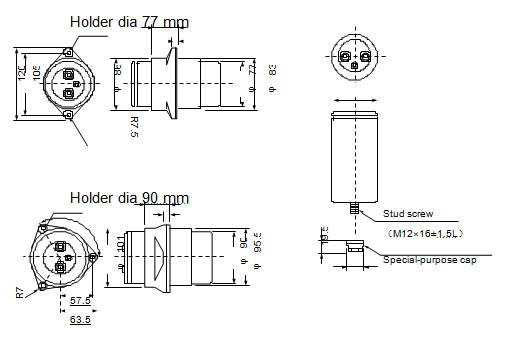

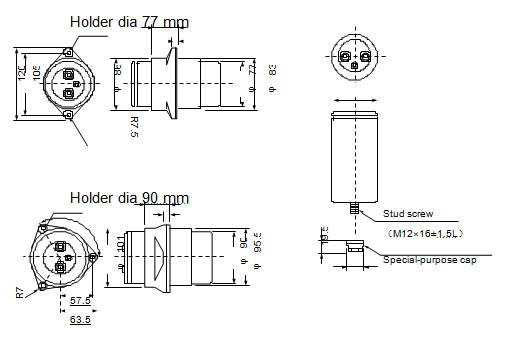

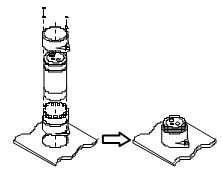

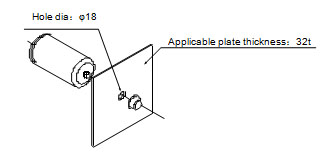

(1) Insulation holder Best suited for improving insulation and vibration resistance and for cutting back on assembly costs. (For

details, see the Technical Report.)

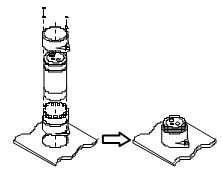

(2) Stud screw capacitor Best suited for cutting back on assembly costs. (For vibration and dielectric resistance, consult

and dielectric resistance, consult

Capsun on a separate basis.)

(3) Other:Useful not only as capacitors but also as a part of a capacitor unit.

Aluminum electrolytic capacitors may cause an explosion, fire, or other serious trouble if not used under specified operating

conditions. Please familiarize yourself with the instructions given below before using these capacitors

Operating temperature and ripple current

1. Keep the operating temperature and ripple current in specified ranges. Applying an excessive current to a capacitor will overheat it, resulting perhaps in short-circuit, ignition, or other fatal fault.

2. A capacitor is also a heating component itself. Please be on guard, remembering that it heats up the inside of the equipment. Run the unit under normal conditions and check the temperature of the surroundings of the capacitor.

3. The permissible ripple current tends to decline with a rise in the atmosphere temperature (the temperature of the surroundings of the capacitor). Consider a permissible ripple current at the maximum predictable atmospheric temperature. Allow also for the changes in frequency.

Applied voltage and connections

1. Capacitors have polarity. Applying a reverse voltage or AC voltage to a capacitor may cause a fire or other fatal fault.

2. Use a bipolar capacitor for circuits whose polarity reverses. However, in this case, like any other case,refrain from using such a capacitor in AC circuit.

3. When an AC component is superimposed on a DC voltage, prevent the peak value from exceeding the rated voltage. An excessive voltage may cause a short-circuit, fire, or other fatal fault.

4. When connecting more than one capacitor in parallel, consider the resistance of the wiring. Establish the connections so that the wiring resistance will be equal at every capacitor.

5. When more than one capacitor is connected in series, all capacitors must be of identical ratings. Then connect the balancing resistors in parallel. At that time, design the circuit so that the voltage levels applied to all capacitors become equal.Check that the voltages applied to capacitors do not exceed a rated voltage.

6. Do not use such a capacitor for a circuit that is repeatedly charged and discharged quickly. If you are to use such a capacitor for a welding unit or for other charging and discharging purposes, use a capacitor designed on a separate basis.

7. Even slow recharging may shorten the service life of a capacitor if its voltage changes greatly. Check it sufficiently as installed on a larger machine or consult Capsun.

Capacitor insulation

1. Do not connect the blank terminal (reinforcing terminal) of a multi-terminal (three- or four-terminal) product of the snap-in type to another circuit. It may cause a short circuit.

2. The external sleeve of the snap-in type has no insulator. If you need a sleeve with an insulator, consult Capsun.

3. Ensure a completely open circuit between the case and the cathode terminal, and between the anode terminal and circuit pattern

Operating conditions

1. A splash of water, salty water, oil or other electrically conductive liquid on a capacitor or using a capacitor when it has dew on it may cause a breakdown. Oil on the rubber sealing or safety vent may cause a decline in airtightness. Do not use a capacitor with liquid on it.

2. Do not use or leave a capacitor in a place where there is a hydrogen sulfide, nitrous acid, sulfurous acid, chlorine, bromine, or other halide compound gas, ammonia, or other hazardous gas. The ingress of any of the aforementioned gases into a capacitor may corrode it. Avoid fumigating and spraying an insecticide as well.

3. Do not use or leave a capacitor in a place exposed to ozone, ultraviolet ray, or radiation.

4. Do not use a capacitor in a place where vibration or impact is excessive.

Installa tion Before installaton

1. Do not reverse the polarity. Do not use a capacitor to which a reverse voltage is applied, even if it looks problem-free. It must be greatly damaged.

2. Do not tighten the curled part (case sealed part) with a mounting fitting or otherwise stress it. Any such practice may cause a liquid leak or sleeve breakage.

3. Dropping or otherwise impacting a capacitor may result in a decline in its electric performance,causing a breakdown. Therefore do not cause an impact on it.

4. Do not reuse a capacitor which has been installed on a machine and energized. No capacitor can be reused except for those removed to measure their electric performance for a periodic checkup.

Method of installation

1. Do not make the safety vent (cap side) of a screw terminal type face downwards. The safety vent may let the electrolyte or compound leak.

2. Do not install a wiring or circuit pattern near the safety vent. When the safety vent is activated, the electrolyte may jet out, resulting in a fire or other secondary accident.

3. Avoid installing a heating part around a capacitor or in back of a printed wiring board (beneath the capacitor).

4. Do not hamper the activation of the safety vent. Above the safety vent (where a screw terminal type is installed on the terminal side, or snap-in type on the case bottom), allow for the following clearances:

Capacitor diameter Clearance

20∼35 mm dia or more 3 mm or more

40 mm dia or more 5 mm or more

PS2, US2 series 1 mm or more

On-board self-supporting

type (snap-in type) capacitor

1. Soldering such a capacitor as floated from a wiring board may result in one of its terminals breaking or its pattern peeling off when vibrated. Insert a capacitor correctly and tightly into specified holes in the wiring board, then solder it.

2. Flux on the rubber sealing may result in corrosion. Therefore do not let any flux stick to any part other than the terminals.

3. Perform soldering at 260°C for no more than 10 seconds or at 350°C for no more than 3 seconds.Exceeding any specified soldering condition may result in a decline in its electric performance,leading to trouble. Dot not let the tip of the soldering iron contact the capacitor.

4. For cleaning flux, Capsun recommends an aqueous or upmarket alcohol detergent or isopropyl alcohol. The recommended concentration of flux with regard to a detergent is 2wt% or less.Excessively high flux concentration may cause corrosion due to the halide. For other detergents,consult Capsun.

5. Do not let any flux stick to any part other than the terminals.

6. Dry the detergent well and do not let any of it remain on the capacitor. Even when you are not cleaning the flux, dry the flux itself. A residue of detergent or flux may cause the halide to penetrate the rubber sealing, leading to corrosion. The snap-in type comes in models protected with epoxy resin. For such models, consult Capsun.

7. When fixing a board and a capacitor with a coating agent or fixative, use a substance containing no halide compound.

In that case, dry the flux or detergent well in advance, then apply a coating. Do not let the coating block the entire surface of the sealing. Any halide compound contained in the coating may result in corrosion.

8. If the safety vent of the capacitor is installed on the printed wiring board, drill a gas bleeder hole to let out the gas when the valve is activated, according to the location of the safety vent. 9. Do not twist or otherwise physically move the capacitor after soldering it on a printed wiring board.

10. Do not solder a capacitor as dipped in a solder bath. Solder it only to the back face of the opposite side to the capacitor, via a printed wiring board.

11. Do not use a fixative or coating agent containing a corrosive, such as a halogen-based solvent.

12. Avoid whenever possible the use of an ozone-depleting substance used in a detergent or other material, in order to protect the earth.

Screw terminal capacitor

1. The terminal screws, recommended tightening torques, and permissible terminal currents are as listed below. Consult Capsun if you wish to use such a capacitor on a machine that vibrates greatly.

Terminal Recommended torque (permissible level) Permissible terminal current

M5 2.2(1.5∼3.0) 60

M6 3.0(3.0∼3.5) 100

M8 7.5(7.0∼8.0) 120

2. The terminal screws furnished in a separate shipment are geared to wires no more than 2 mm thick.For wires more than 2 mm thick, ensure a screw length allowing for that thickness.

3. Capsun recommends a bar hole diameter of 6 mm for M5. An excessively large hole diameter may result in poor contact between the terminal surface and bar, causing a local heatup and thus a breakdown.

Storage

1. Store all capacitors indoors at a temperature of 5-35°C, at a humidity of no more than 75%RH (25°C), avoiding direct sunlight. The maximum shelf life of capacitors is 3 years. All capacitors which have been on the shelf for more than 3 years have an excessively high leakage current. Treat them with appropriate voltage and use them.

2. Store them under the same operating conditions as mentioned above, except for the temperature and humidity.

3. Store them as packed whenever possible.

4. Restriking may have caused an electric charge. Do not touch the terminal with a bare hand. Any such touch might give you an electric shock. Discharge all capacitors with a resistor (10-100?) or a discharge plate before use

Test run

1. Do not touch terminals of a capacitor with a bare hand. Any such touch might give you an electric shock.

2. Do not short-circuit a capacitor between terminals with an electrically conductive material.

3. Do not apply an acid, alkali, or other electrically conductive solution to a capacitor.

4. For the operating conditions of capacitors, check the "Design Operating Conditions.

Maintenance and servicing

1. Conduct a periodic checkup on capacitors for industrial equipment. The checkpoints are:

(1) Appearance: Status, liquid leakage and other considerable trouble with the safety vent

(2) Electric performance: Capacity, loss, leakage current, and other items specified in the delivery specifications.

The standard temperature for measuring electric performance is 20°C. Leave a capacitor at 20°C and wait for the inside of the capacitor to reach a specified temperature before taking measurements. To learn whether to use such a capacitor, consult Capsun. Before a periodic checkup, turn off the switch and discharge the capacitor completely.

2. Replace all capacitors whose service lives have reached their end. When making a replacement, replace all

capacitors. Using an old one together with a new one may cause an imbalance in the ripple current or voltage sharing

In an emergency

1. If a gas is detected while such capacitors as installed are used, turn off the main power of the installation or unplug the power cord from the wall outlet.

2. When the safety vent of a capacitor is activated, a hot gas exceeding 100°C will jet out. Do not make your head come close to it or go close to a place exposed to the gas.

3. Should a gas jet enter your eye, wash it immediately with clean water.

4. Should an electrolyte get into contact with your skin, wash it with soap and water. Never put it into your mouth

For scrapping

1. Scrapped capacitors are classified as scrapped metal. In the case of burial, they are handled as controllable industrial wastes because of the nature of the contents (electrolyte). Commission the task to a specialist industrial waste disposal agent. Make sure that no waste product enters the market.

2. Most of the material is aluminum and cannot be completely burned. In burning, consider the following:

?Burning them as enclosed may cause an explosion. Either open up a hole or bust the opening.

?Because of the exterior material (polyvinyl chloride), cold burning may cause emissions of hazardous gases. Burn the material at high temperatures. (Burning requires the sorting of exterior material.)

3. Demolishing a capacitor may cause an injury, electric shock, or other trouble. Therefore avoid it.

Other

1. For details, see the Guidelines on the Operation of Fixed Aluminum Non-solid Electrolytic Capacitors for Electronic Equipment EIAJ RCR-2367.

2. For questions, consult Capsun or http://www.szcapsun.com

(1) Insulation holder Best suited for improving insulation and vibration resistance and for cutting back on assembly costs. (For

details, see the Technical Report.)

(2) Stud screw capacitor Best suited for cutting back on assembly costs. (For vibration

and dielectric resistance, consult

and dielectric resistance, consultCapsun on a separate basis.)

(3) Other:Useful not only as capacitors but also as a part of a capacitor unit.